|

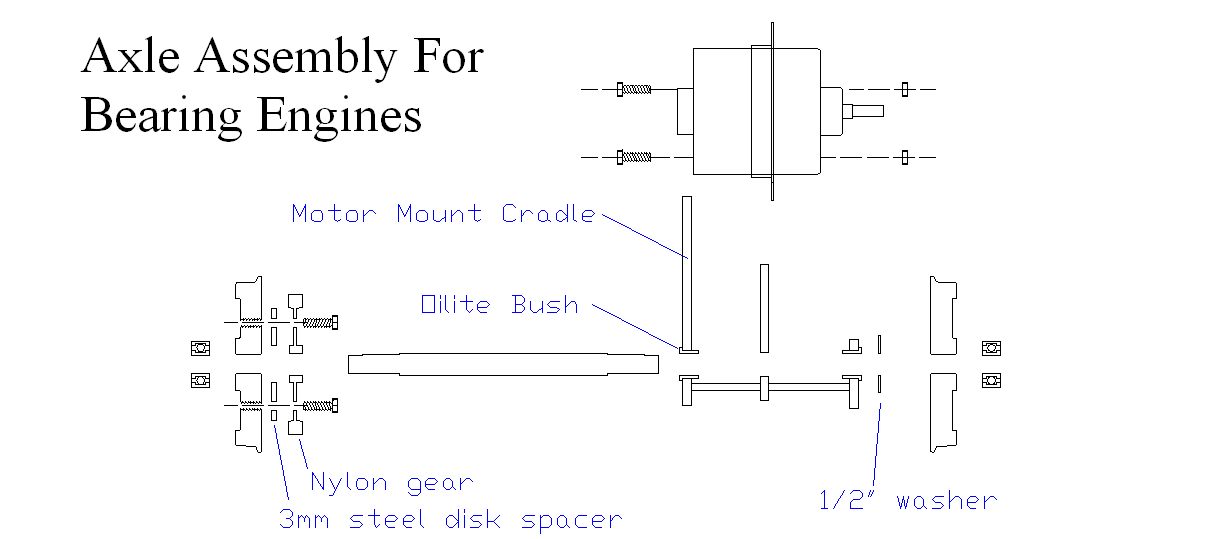

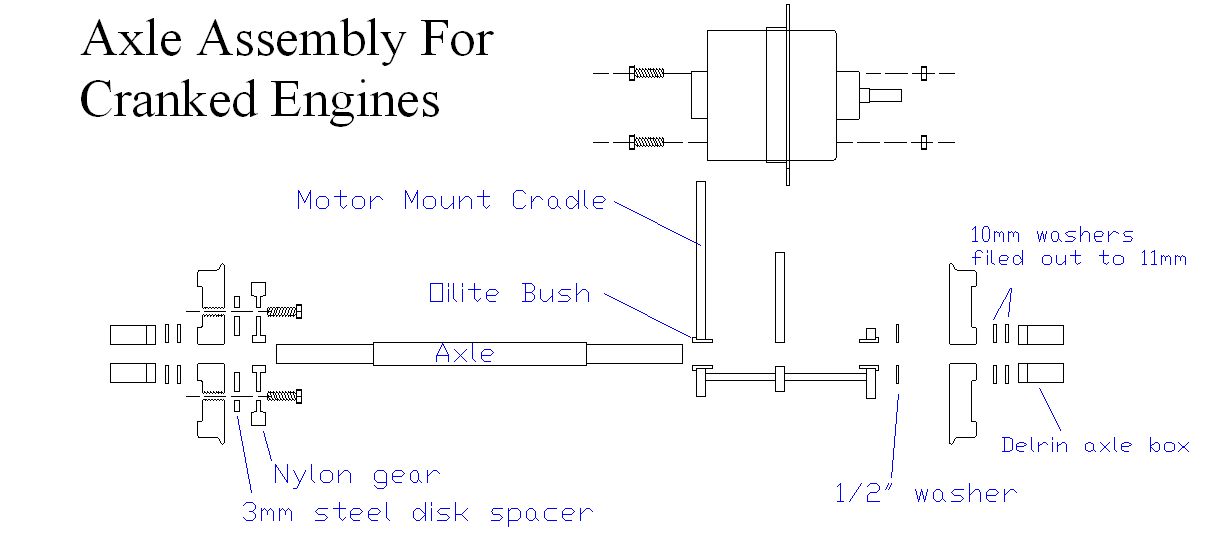

- When fitting the

1/2" oilite bushes to the motor mounts, make sure you insert the

bearing two one way round and two the opposite way per bogie.

- We suggest fitting

with bearing fit. Wipe external

face of the bush with thinners or solvent to remove oil before applying

bearing fit.

- To stop lateral

movement of the motor mount on the axle it may be necessary to fit a

spacer washer at the non gear end of the cradle. Very slight pla is

acceptable but excessive movement may affect the meshing of the gears.

Pressing on the

wheels

Before pressing on the drive wheel, slightly loosen the three

bolts on the nylon gear. This allows the gear to centre on the axle rather than

the bolts. Apply bearing fit to the inside of the wheel and the axle shaft. Only

press the driving wheel on at this stage as you need to build the motor assembly

on the axle.

|

|

CAREFUL - we use a broaching press as you get a good feel for the pressure requires and how the axle/wheel is moving.

When pressing on the wheel place the wheel on the base plate of

the press and press the axle down. Do not push the axle in one go but release

the pressure after the first few milimetres. This makes sure that the axle is

going in straight.

Some hydraulic presses can easily bend the axle or bell the end of the axle.

If too tight then put the wheels in an oven and

heat to 150 deg C and the axles in a freezer. This should be enough to

help ease them on. With this method the tailstock of a lathe should be surfice to press wheels on.

When pressing the bearings you may have to

slightly reduce the diameter of the axle end. If the bearing is too

tight it may crack the bearing.

|

Apply bearing fit/ thread lock to the 3no. 15mm bolts and bolt the Delrin gear tight to the back of the wheel.

|